ONLINE MEETINGS PLATFORM - EXHIBITORS ITM 2021

AMS International Sp. z o.o. activities are connected with the software and IT consultancy services. Increasing of accuracy and productivity, automation, improvement of the quality of parts, shortening of the process time and reduction of possible errors are the most important features of the offered software.

AMS International offers complete CAD/CAM solutions, adapted to Customers' needs. The company provides advanced implementation services based on the knowledge of our experienced engineering department, conducts training courses and provides servicing of software.

Contact details:

AMS International Sp. z o.o.

aleja Piłsudskiego 4f/3

05-077 Warszawa

+48 22 299 09 79

biuro@i-ams.com

https://www.linkedin.com/company/ams-international-sp-z-o-o

The Dltech company has been on the market for over 11 years, we deal with the optimization of production processes. We prototype machines and devices for industry, we design and manufacture machines and entire production lines for the largest companies in Poland and Europe.

They use our services

- manufacturers of roof accessories

- manufacturers of insulation materials

- plastic processing

- textile industry

- wood industry

- automotive

We specialize in fast rewinding and confectioning of materials, industrial bonding technology, joining and coating of various types of materials

On the Polish market, DMG MORI Polska offers products of one of the world's leading manufacturers of metalworking machines, the DMG MORI concern. The company deals with both the sale and servicing of numerically controlled machine tools. We have 14 production plants located in Poland, Germany, Italy and Japan. Together with the production plant in Poland, we represent 5% of all employees of the DMG MORI concern.

DMG MORI Polska, operating on the Polish market for 20 years, also implements solutions for service support, the task of which is to increase the availability of the service. The currently functioning structure is the result of many years of practice and experience. Our customers can be confident about the stability of machine tools, because their technical efficiency is ensured by an extensive service network. The smoothness of your production is supervised by 34 service engineers and 9 technology engineers located in several regions of our country.

The main strategy of DMG MORI Polska is professional consulting and building trust based on mutual benefit. Our goal is to constantly improve machining processes, reduce costs and increase the technological level.

From DMG MORI:

“Digitization and automation are changing our world quickly, radically and irretrievably. Participation in this process, project, platform is "the future of our country, our economy, our enterprises and their participation in the global supply chain". It is our "to be or not to be". It is our responsibility to take advantage of the opportunities provided by DMG MORI Polska as part of the project. We try to encourage our current and future partners to take advantage of the opportunities available and available thanks to DMG MORI Polska. This is not just "digitization", it is progress and the future of all of us. With DMG MORI you can participate in or continue technological, structural and cultural development ”. - Marek Osiński, President of the Management Board.

HKK provides comprehensive Auto ID solutions. We operate intensively both on the Polish and European market. Almost 20 years of experience allows us to accurately implement even the most difficult customer orders. The high quality of our services is based on such important features as enormous substantive knowledge of the company's employees, perfect suppliers and a reliable machine park. Our main pillars of operation are: distribution of the highest-class Auto ID devices, providing IT solutions for warehouse management (WMS systems) and POS systems, as well as the production of self-adhesive labels. Our team of professionals successfully implements optimization projects in every industry.

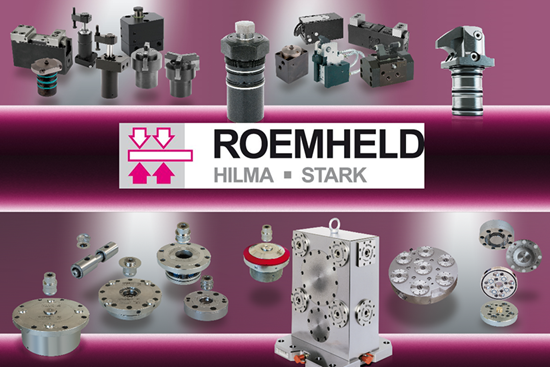

Roemheld, together with the specialists in fastening technology Hilma-Römheld and Stark, form a strong GROUP offering a wide range of fastening technology products for the manufacturing industry. The ROEMHELD Group employs approximately 500 people and generates an annual turnover of EUR 105 million.

We supply clamping systems and components for machining jigs, zero point clamping systems, general purpose hydraulic cylinders and components, SMED solutions - clamping and tool changing systems in presses, components for ergonomic parts manipulation and workplace organization, and linear actuators.

Metalshub is a metals and ferroalloy trading platform available and used worldwide by steel mills and foundries. We provide a safe and fast process of conducting small and large on-line transactions. In addition to providing infrastructure for trade, we have integrated logistic services, trade financing services and credit insurance with the platform. In addition, we offer the first ferroalloy price indices based on real trading data. More than 1,200 companies can be found on the platform and the transaction volume has already exceeded EUR 700 million per year.

MTM MODELE is based in Bodzanów near Wieliczka. The company started its activity in 2009, specializing in the production of large-size casting models. All members of the management staff are graduates of the Faculty of Foundry Engineering at AGH. In 2013, a new production plant was created, equipped with the latest technologies, extending the company's offer. Currently, MTM MODELE is one of the largest modeling shops in Poland, offering models made of wood, plywood, resins, aluminum and laminates in every size range. We invite you to watch the movie https://www.youtube.com/embed/VWoUcMO914A

The company POLTEKNIK Ltd. Sp. z o.o. We cordially invite you to contact us online on the ITM 2021 Internet Meeting Platform, where we will present our offer regarding machines for sheet metal forming and thermal cutting, as well as solutions in the field of production automation.

We work with proven suppliers whose machines have been present on the Polish market for several years and have confirmed their quality and advanced technological level. Our experienced and proven service team watches over the reliability of the delivered devices and workstations.

We invite you to contact our specialists!

For 12 years, RICHO Polska has been supplying CNC machine tools for metal on the Polish market. The company has successfully installed over 250 machines, such as CNC lathes, machining centers, CNC carousel lathes, grinders, boring machines, laser cutters, robots, bar feeders.

New products are laser cutters (fiber laser), presses and industrial robots.

RICHO Polska is a member of the Bydgoszcz Industrial Cluster, which brings together companies from the tool industry and plastics processing. We sell CNC machine tools, on which we also process metal.

We guarantee their quality, accuracy and service.

Reesink Logistics Solutions (RLS) is a European leader in the distribution and implementation of the intelligent and innovative AutoStore storage system and one of the leading warehouse system integrators in many European countries, and recently also in Poland.

During the Modernlog fair, RLS Poland invites you to an interactive and multimedia stand where visitors will be able to directly learn about the mechanism and details of the AutoStore system operation. It will also be a great opportunity to get to know the offer and development plans of RLS on the Polish warehouse and logistics market.

The Technical Association of Polish Founders (STOP) deals with the organization of industry training courses, conferences, symposiums and technical trips, as well as the promotion of the foundry industry. Publisher of the only magazine in Poland devoted to the foundry industry - PRZEGLĄD ODLEWNICTWA.

WAMECH is a Polish family company dealing in the production of internal transport devices for industrial plants. The range of products offered includes logistic trains, platforms and trolleys for transporting raw materials. Under the REDGE brand, we develop the distribution and implementation of AGV self-propelled trucks. We also offer production outsourcing services, in particular for welded products. Several dozen years of experience allow us to advise clients and make modifications to our standard products or create dedicated solutions fully tailored to the expectations of the customer.

Wivia Machinery Co.,Ltd. is a professional Swiss type CNC lathe manufacturer located in Taiwan. We have invested a lot of time to develop the Swiss turning center. Besides, more convenient for users we have considered when we have designed each new machine. We call it “human-based design”.

W series and SW series has double spindle system with Y axis. These machines possess milling, drilling, tapping, and cutting precise parts. The synchronous machining can economize time.By our producing quality control system, we can make sure every CNC machines on standard operating procedure, and no anyone machine can be sold before passing machining test.

Wivia also provide fastest service for customers after sale, because customer totally satisfaction is our target. Our products are applied to aerospace, automobile, electric machining, medical parts, clock / watch and other industries.

Wivia will be the best choice.

Our passion is to combine science and business. By developing for the industry as part of the project "Retrofitting the Technology Hall in the e-Production Laboratory implementing the concept of Industry 4.0", we increase the research capabilities of our department, among others o research related to the application of augmented reality, cooperation between robots and humans, IIoT technology, EMC research.

Project co-financed by the European Union from the European Regional Development Fund under the Regional Operational Program for the West Pomeranian Voivodeship 2014–2020.

Project co-financed by the Minister of Education and Science

.